- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-12 Origin: Site

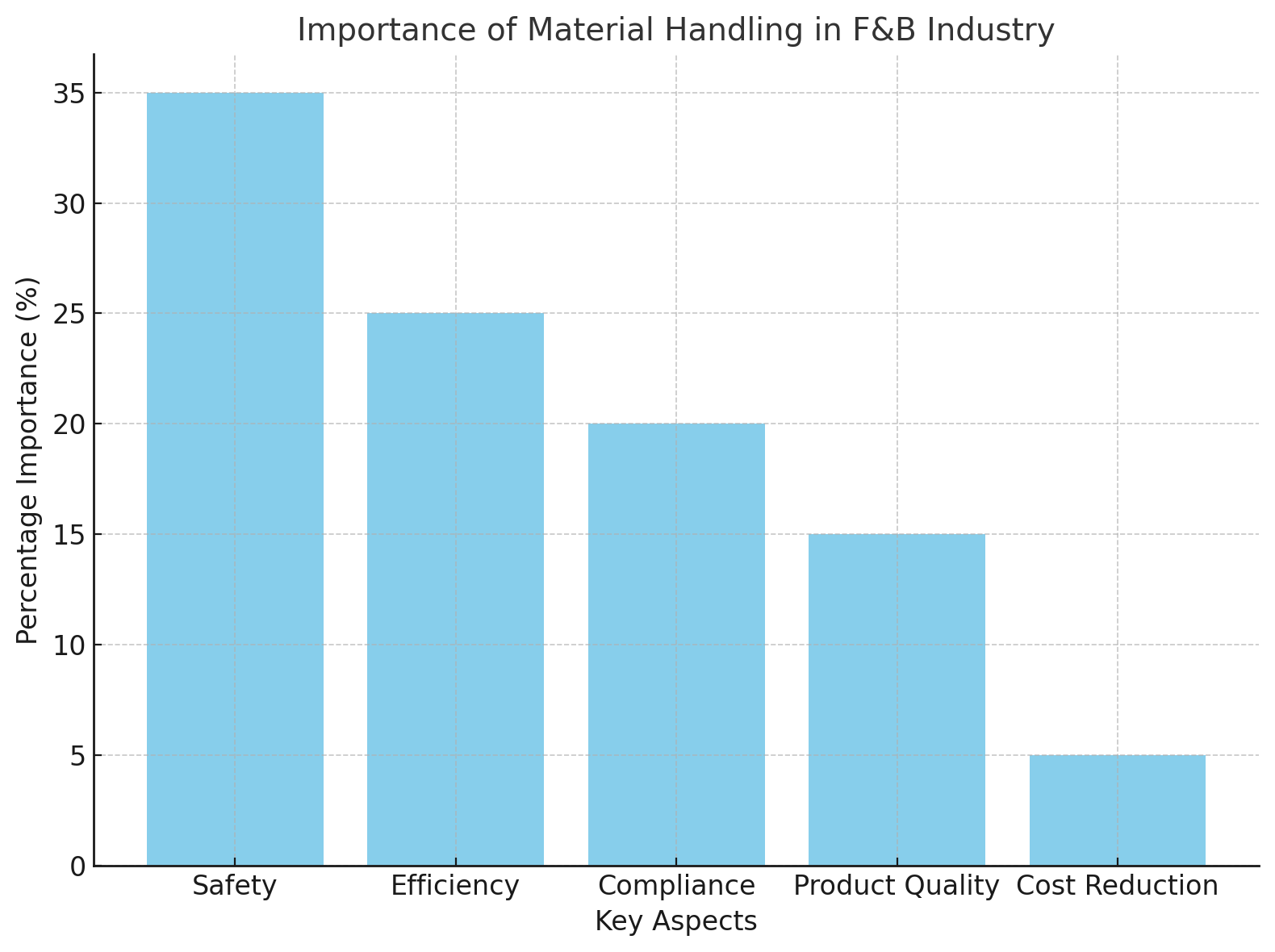

Material handling is critical in the food and beverage (F&B) industry. Improper handling can lead to contamination, safety hazards, and significant losses. This can affect both food safety and production efficiency.

In this article, we will explore why material handling is essential to the F&B industry. We will also discuss how innovative solutions, like Vacuum Lifters, improve safety, quality, and operational efficiency.

The F&B industry is highly regulated when it comes to hygiene and safety, and for good reason. Poor material handling can introduce contaminants and pathogens, potentially leading to foodborne illnesses, recalls, and significant harm to public health. Proper handling is necessary to prevent such issues, ensuring that food products remain uncontaminated throughout the production process.

Maintaining Product Integrity

From the raw materials to the finished products, ensuring the integrity of food is paramount. Improper handling can cause damage to food products, leading to waste and reduced quality. For example, delicate items like fruits and baked goods require careful handling to prevent bruising or spoilage. Using systems like Vacuum Lifters, which gently lift and transport products without damaging them, helps maintain high product quality and safety.

Efficient material handling systems can drastically reduce downtime, streamline processes, and boost productivity. When materials are moved smoothly from one stage to another, workers can focus on other tasks, leading to faster production cycles. Automation, such as the use of Vacuum Lifters, can significantly increase the speed at which goods are handled, reducing the need for manual labor and cutting down on production bottlenecks.

Benefit | Description |

Safety | Reduces the risk of worker injuries and contamination by using automated systems like Vacuum Lifters. |

Efficiency | Streamlines operations, reducing downtime and increasing productivity. |

Compliance | Ensures adherence to safety and health regulations, minimizing the risk of fines. |

Cost Savings | Helps reduce labor and operational costs while improving throughput. |

Impact on Cost and Time

Reducing material handling time can lead to significant cost savings. The more efficient the system, the less time and labor are needed to transport materials, directly affecting the company’s bottom line. Furthermore, automated systems, like Vacuum Lifters, reduce the chance of human error, ensuring that production is not interrupted by mishandling or accidents, which could otherwise lead to costly delays.

The F&B industry faces strict health and safety regulations. Compliance is essential, not only to avoid legal consequences but also to maintain the trust of consumers. Proper material handling ensures that all hygiene standards are met, and food products are processed and stored according to guidelines. Systems such as Vacuum Lifters provide the precision and control needed to ensure that materials are handled in compliance with industry regulations.

Reducing Risks of Non-compliance

Failure to adhere to safety protocols can result in fines, legal consequences, and a damaged reputation. By adopting efficient and regulated material handling systems, such as Vacuum Lifters, companies ensure they are meeting the necessary standards while maintaining operational efficiency.

Challenges of Manual Handling

Manual material handling is labor-intensive and can lead to a range of health issues for workers, including musculoskeletal injuries, strains, and fatigue. Additionally, human error can lead to damaged goods, delays, and inefficiencies. With the increasing demand for high volumes of products, manual handling alone is no longer sufficient to meet the production needs of F&B companies.Benefits of Automation

Automated material handling systems like Vacuum Lifters offer a solution to these challenges. These systems reduce the need for human intervention, lowering the risk of injury while increasing the efficiency and speed of material handling. Vacuum Lifters, for instance, allow workers to move heavy or bulky items with ease, minimizing physical strain and preventing workplace injuries.

Feature | Manual Handling | Automated Systems (e.g., Vacuum Lifters) |

Labor Intensity | High, requires more workers and effort. | Low, minimizes the need for manual labor. |

Risk of Injury | High, leads to musculoskeletal injuries. | Low, reduces physical strain on workers. |

Efficiency | Slower, prone to errors and delays. | Faster, improves accuracy and productivity. |

Cost | Higher long-term costs due to labor. | Reduces labor costs and downtime. |

Conveyors, Pallets, and Lifting Tools

Conveyors are essential for moving goods efficiently along production lines, while pallets are widely used for bulk storage and transport. Lifting tools, including cranes and hoists, help move heavy items safely. However, for specific tasks, such as lifting large sacks or bulky boxes, Vacuum Lifters are an ideal solution. They offer versatility in lifting different types of loads with minimal physical effort.

Vacuum Lifters

These systems use suction to safely lift and transport materials without causing any damage, making them ideal for delicate food products or heavy loads. Vacuum Lifters are particularly effective in environments where hygiene and safety are paramount, such as in food processing facilities, where they help prevent cross-contamination.

Equipment | Purpose | Benefits |

Conveyors | Move products along the production line. | Increases speed, reduces labor costs. |

Pallets | Storage and transportation of goods. | Simplifies handling, supports large loads. |

Vacuum Lifters | Lifting heavy or bulky items. | Reduces injury risk, improves handling efficiency. |

Lifting Tools | Used for manual handling of products. | Enhances worker safety, provides ergonomic support. |

Tailored Solutions

Choosing the right equipment depends on the type of material being handled, the volume of work, and the specific needs of the F&B production process. While conveyors and forklifts might be suitable for certain tasks, Vacuum Lifters are particularly beneficial in handling fragile, heavy, or awkward loads with precision and care.

Cost Considerations

While automation can require an upfront investment, the long-term benefits far outweigh the costs. Reducing labor costs, improving productivity, and reducing the risk of injury all contribute to a more profitable and sustainable operation.

Common Injuries in F&B Handling

Material handling often involves repetitive lifting, bending, and reaching, which can cause musculoskeletal disorders (MSDs) and other injuries. The physical strain from lifting heavy or awkward loads is a common cause of workplace injuries in F&B settings.How Modern Equipment Reduces Injuries

Using equipment like Vacuum Lifters to move heavy or bulky items reduces the physical strain on workers. These systems are designed to minimize manual lifting and enable employees to perform their tasks more efficiently without risking injury.

Injury Type | Percentage of Total Injuries | Preventative Measure |

Musculoskeletal Disorders | 30% | Use of Vacuum Lifters to reduce lifting strain. |

Slips, Trips, and Falls | 25% | Improved ergonomics and safer equipment like Vacuum Lifters. |

Cuts and Bruises | 20% | Use of safety equipment and automated systems to prevent direct contact. |

Repetitive Strain Injuries | 15% | Implementation of automated material handling systems like Vacuum Lifters. |

Improving Worker Comfort

Ergonomically designed equipment plays a crucial role in reducing strain and discomfort. By incorporating features that adjust to different worker heights and task requirements, ergonomic solutions, including Vacuum Lifters, ensure that workers can perform their duties without unnecessary physical strain.

Ergonomic Design Features in Equipment

Vacuum Lifters are designed with ergonomic features that reduce the need for bending, lifting, or twisting, which are common causes of injury. These lifters provide operators with a more comfortable and safer way to handle materials, contributing to overall worker well-being.

Delicate Handling of Food Products

Food products, particularly those that are delicate or perishable, require gentle handling to maintain their quality. For example, fruits, vegetables, and baked goods must be carefully lifted and transported to avoid damage, spoilage, or contamination.How Equipment Improves Quality Control

Vacuum Lifters ensure that products are safely transported with minimal risk of damage. These lifters can handle delicate items, providing a secure grip that prevents bruising, squishing, or contamination during the transport process.

Keeping Products Safe and Identifiable

Traceability is vital in ensuring that food products meet the required safety standards and are not compromised during handling. Automated systems like Vacuum Lifters can be integrated with tracking systems to monitor the movement of materials and ensure compliance with quality standards.

Role of Technology in Tracking

By using technology to track materials throughout the production process, F&B companies can ensure that all products are handled correctly and meet regulatory requirements. Vacuum Lifters can be incorporated into these systems to optimize product handling and traceability.

Efficiency Gains

Automating material handling processes with systems like Vacuum Lifters can significantly reduce labor costs. These systems streamline operations, allowing fewer workers to manage higher volumes of products.

Case Study

A case study could demonstrate how a company implementing Vacuum Lifters reduced the number of workers required for manual lifting tasks, resulting in lower labor costs and improved operational efficiency.

Cost of Product Loss

Improper handling can lead to product loss and spoilage, costing companies both in terms of lost inventory and wasted resources. By using proper material handling equipment, such as Vacuum Lifters, businesses can reduce waste and ensure that products arrive at their destination in the best possible condition.

How Handling Systems Help

The use of equipment like Vacuum Lifters ensures that products are handled gently, reducing the risk of damage and wastage. This translates into cost savings and improved profitability for the company.

Emerging Technologies

Automated systems, including robotics and advanced conveyors, are transforming material handling in the F&B industry. These innovations improve efficiency, safety, and traceability, ensuring that products are handled more effectively.Vacuum Lifters

Vacuum Lifters are at the forefront of this technological revolution. They provide a safe and efficient way to move heavy or delicate materials, reducing the need for manual labor and increasing productivity.

The Shift Towards Smart Systems

As the F&B industry continues to embrace technology, smart systems powered by IoT (Internet of Things) are becoming a key part of material handling. These systems allow for better data analysis and real-time adjustments, improving efficiency and reducing costs.Sustainability

Sustainable practices are becoming increasingly important in the F&B industry. By using energy-efficient equipment like Vacuum Lifters, companies can reduce their environmental footprint while improving their operational efficiency.

Effective material handling is essential in the F&B industry for ensuring food safety, product quality, and operational efficiency. As the industry evolves, adopting modern solutions like Vacuum Lifters is crucial for staying competitive and meeting regulations.

Investing in Vacuum Lifters and other innovative handling solutions helps F&B businesses optimize operations, improve safety, and enhance product quality. With sustainability and efficiency becoming more important, these smart solutions future-proof operations and ensure long-term success in the competitive F&B sector. Escott is committed to providing these cutting-edge solutions to help businesses thrive.

A: Material handling ensures food safety, product quality, and operational efficiency. Efficient systems, like Vacuum Lifters, help reduce contamination risks and improve workflow.

A: Vacuum Lifters provide safe lifting solutions for heavy or bulky items, reducing manual labor and the risk of workplace injuries while maintaining product integrity.

A: Automated systems, such as Vacuum Lifters, streamline operations, reduce labor costs, and enhance safety by minimizing physical strain and improving handling accuracy.

A: Vacuum Lifters reduce the physical strain on workers by handling heavy loads efficiently, preventing injuries like strains and sprains, and ensuring a safer working environment.

A: When selecting equipment like Vacuum Lifters, consider efficiency, safety, ergonomic design, and the ability to meet industry-specific needs while ensuring compliance with regulations.