- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-14 Origin: Site

Vacuum measurement plays a critical role in many industries. Have you ever wondered how a Vacuum Lifter can safely lift heavy objects? Accurate vacuum measurement ensures efficiency in such systems.

In this article, we will dive into the methods, units, and scales used to measure vacuum, specifically focusing on their importance for vacuum lifters. You'll learn how these measurements impact performance and safety in various applications.

A vacuum is essentially an environment where the air pressure is lower than the surrounding atmosphere. It is a critical factor in many applications, including manufacturing, laboratory research, and material handling systems, such as vacuum lifters. Vacuum measurement quantifies the level of vacuum achieved in a system and helps ensure that processes operate within required pressure ranges.

Vacuum measurement plays a vital role in ensuring precision in manufacturing and scientific research. For example, in a vacuum lifting system, the vacuum pressure needs to be accurately measured to ensure that it can lift materials safely and efficiently. Furthermore, understanding vacuum levels helps in troubleshooting and adjusting systems for optimal performance.

A vacuum is a state where the pressure is lower than the atmospheric pressure, resulting in an environment with fewer air molecules. Essentially, vacuum measurement gauges the amount of negative pressure in a system caused by the absence of air or reduced air density.

An ideal vacuum, also known as a perfect vacuum, would theoretically have no particles or air molecules. However, in practice, a perfect vacuum is unattainable. Even outer space, which is often considered close to a vacuum, contains a few hydrogen atoms per cubic meter. This concept of an ideal vacuum serves as a reference point for measuring the quality of vacuum systems, though achieving it is not physically possible.

Vacuum measurement is used across a variety of industries. In semiconductor manufacturing, precise vacuum conditions are required for etching and deposition processes. In medical fields, controlled vacuum environments are needed for sterilization and diagnostics. Moreover, in industries utilizing vacuum lifters, the pressure needs to be measured accurately to ensure safe and efficient handling of materials.

In applications like vacuum lifters, precise vacuum measurement is necessary to maintain consistent lifting power. Variations in vacuum levels can affect the lifting capacity, leading to inefficiencies or unsafe conditions. Therefore, accurate vacuum measurement is essential to ensure reliability and optimal performance in all related systems.

The Bourdon tube gauge is one of the most common mechanical devices used to measure pressure in vacuum systems. It consists of a curved tube that straightens as pressure decreases. As the tube straightens, it moves a needle on a dial, indicating the pressure inside the system. It is especially useful in rough vacuum systems where high accuracy is not the primary concern.

The Bourdon tube is robust and reliable, making it ideal for industrial applications, but it becomes less accurate as the vacuum level decreases. It is most commonly used in systems operating within the rough vacuum range.

Capacitance manometers measure vacuum by detecting changes in capacitance as the pressure changes. A diaphragm within the manometer moves in response to the pressure, altering the capacitance between the diaphragm and an electrode. This method provides high accuracy and is suitable for medium to high vacuum ranges.

Piezo-resistive gauges operate on the principle that the resistance of a material changes when subjected to pressure. A sensor with a piezo-resistive element changes its electrical resistance when the diaphragm deflects due to varying pressure. These gauges are commonly used for low-pressure measurements and offer high sensitivity.

Ionization gauges are used to measure ultra-high vacuum conditions by ionizing the residual gas in the vacuum. The process involves bombarding gas molecules with electrons, causing them to ionize. The number of ions collected by an electrode is proportional to the vacuum level. These gauges are typically used in high-precision applications where extremely low pressures are involved.

Pirani gauges measure vacuum based on the thermal conductivity of gas molecules. A heated wire is placed inside the vacuum, and as gas molecules collide with the wire, they remove heat, causing the wire's resistance to change. This change in resistance is proportional to the vacuum level. Pirani gauges are commonly used for rough vacuum measurements.

The Torr unit, named after Evangelista Torricelli, is based on the height of a column of mercury in a barometer. One Torr is equivalent to 1 mmHg, and it is widely used to measure vacuum pressures. The Torr scale is particularly useful in lower to medium vacuum ranges.

Atmospheric pressure is the standard pressure at sea level, typically measured as 760 mmHg. It serves as the reference point for other vacuum measurements. A vacuum condition is defined as a state where the pressure is below 760 mmHg.

The Pascal is the SI (International System of Units) unit for pressure. It is defined as one Newton per square meter (N/m²). In scientific and technical applications, the Pascal is the standard unit used for measuring pressure, including vacuum levels.

Kilopascals and millibars are commonly used in many parts of the world to measure vacuum. One kPa is equal to 1,000 Pascals, and one mbar is equal to 1/100th of a bar. These units are often used in Europe and other regions outside North America.

Microns are smaller units of measurement, particularly useful for high-precision vacuum systems. One micron is equal to 1/1000th of a Torr, making it ideal for measurements in ultra-high vacuum systems, including those used in semiconductor manufacturing.

Inches of mercury are commonly used in the United States for measuring pressures in the rough vacuum range. This unit is derived from the same principles as Torr but measures pressure in inches rather than millimeters.

Unit | Description | Common Use |

Torr | Pressure measured by a column of mercury | Low to medium vacuum ranges |

Pascal (Pa) | SI unit for pressure | Scientific and technical applications |

Microns | 1/1000th of a Torr | High-precision vacuum systems |

Inches of Mercury (inHg) | Derived from mercury barometers | Common in North America for rough vacuum |

Kilopascal (kPa) | Metric unit for pressure | Used outside North America |

Vacuum lifters are used in material handling systems to lift heavy objects using the principles of vacuum pressure. These systems generate negative pressure below a suction pad that attaches to the object being lifted. The vacuum pressure must be maintained within a specific range to safely and efficiently lift materials, such as steel plates, bags of flour, or sheets of plywood.

In vacuum lifters, the vacuum pressure is crucial for lifting performance. Manometers or other gauges are used to measure the vacuum levels. This ensures that the vacuum pump is operating correctly and that the system is capable of handling the required lifting load. In addition, vacuum measurement can be used to detect leaks in the system, which could reduce the lifting capacity.

Measuring vacuum pressure can help pinpoint leaks in a vacuum lifting system. For example, if the vacuum system is not reaching the required vacuum level, the manometer readings can indicate whether there is a leak in the system or a malfunction in the pump.

Issue | Possible Cause | Solution |

Low lifting capacity | Vacuum pressure too low | Check and adjust vacuum pressure |

Inconsistent lifting | Leaks in the system | Inspect for leaks and seal gaps |

Lifter not holding items | Incorrect vacuum range for load type | Ensure appropriate vacuum for material |

Vacuum lifters operate differently depending on the type of material being lifted. Non-porous materials, like metal sheets, require less vacuum power to lift compared to porous materials, such as wood or fabrics. To adjust for this, the vacuum pump capacity may need to be increased to handle the higher air flow required to maintain the vacuum when lifting porous loads.

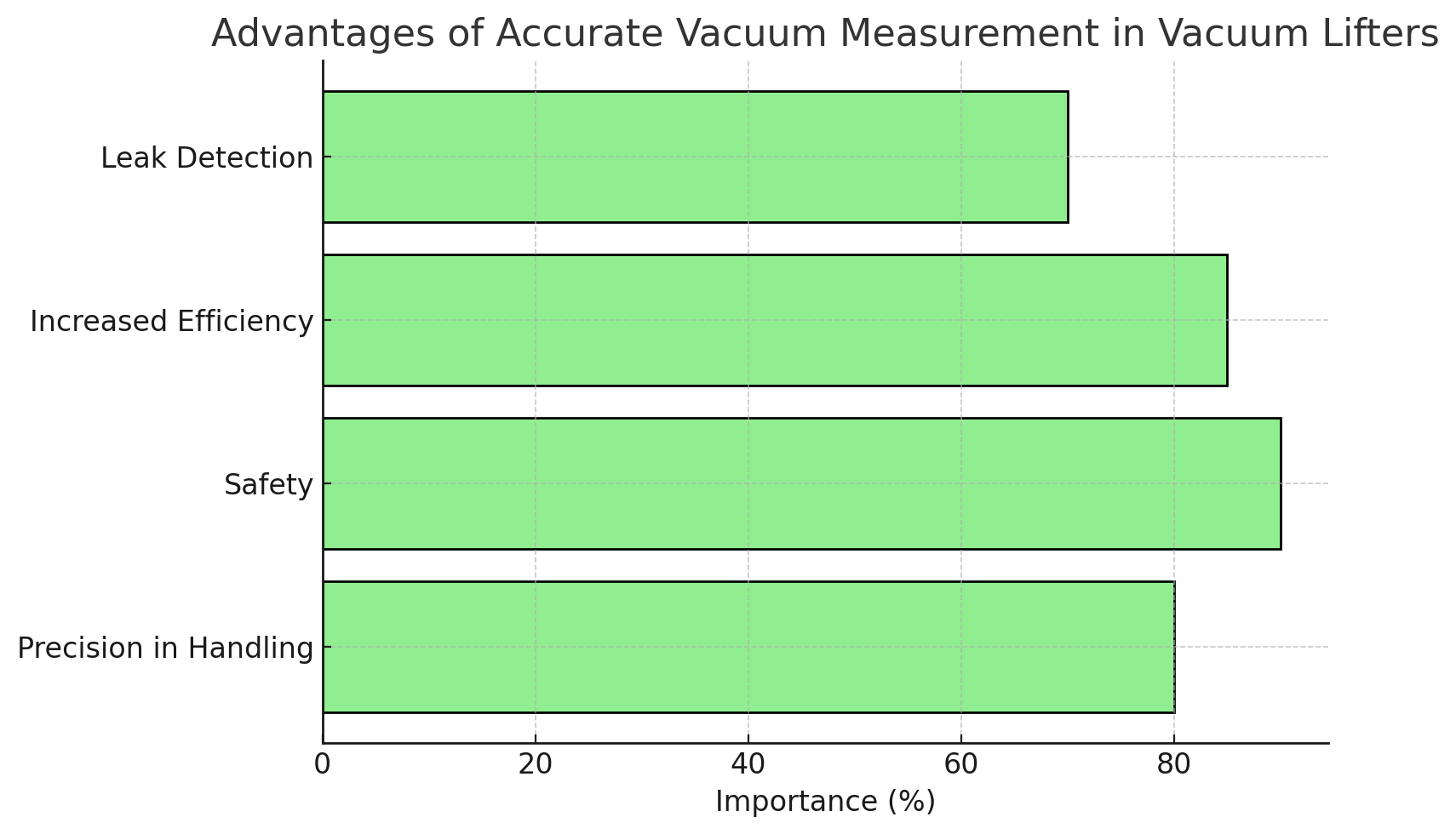

Advantage | Description |

Precision in Handling | Ensures precise control over lifting materials |

Safety | Reduces the risk of accidents due to insufficient vacuum |

Increased Efficiency | Prevents power loss and system inefficiency |

Leak Detection | Helps identify and troubleshoot vacuum system leaks |

Measuring vacuum at very low pressures can be challenging. In high and ultra-high vacuum conditions, specialized equipment such as ionization gauges or capacitance manometers is required. Even small variations in temperature or gas composition can affect the accuracy of vacuum measurements. Additionally, vacuum gauges may become less reliable in extreme conditions.

When selecting a vacuum measurement method, it is essential to consider the pressure range, the required accuracy, and the specific application. For example, a vacuum lifter system may not require the high precision needed for scientific experiments, but the measurements must still be reliable to ensure safe material handling. Balancing cost with accuracy is also important when selecting vacuum gauges for industrial applications.

Vacuum measurement is crucial for various industries, such as manufacturing and material handling. Accurate measurements ensure that systems, including vacuum lifters, operate efficiently and safely. Industries like semiconductor manufacturing and medical equipment sterilization depend on precise vacuum levels. Escott provides reliable solutions for material handling systems, ensuring optimal performance and safety. Their vacuum lifters are designed for precision, helping businesses improve efficiency and reduce risks.

A: A vacuum is a space with reduced air pressure. It is measured to ensure precise conditions in industries like semiconductor manufacturing and vacuum lifters.

A: Vacuum lifters use vacuum pressure to lift heavy objects safely. The pressure must be measured accurately for optimal lifting capacity.

A: Vacuum is typically measured in units like Torr, Pascal, and microns. Each unit serves a different vacuum pressure range.

A: Accurate vacuum measurement ensures vacuum lifters operate efficiently, allowing for safe and precise material handling.

A: If a vacuum lifter isn't performing as expected, check for leaks and ensure vacuum pressure is within the required range for the material being lifted.